Industrial automation

With nearly 25 years of experience, Hexapole is your reliable and full partner in industrial automation. Enterprises from all over Europe know how to find our expert engineers when they look to have operating and automation systems designed, built and implemented. And doing these things is just right up our alley.

Efficiency improvement: Automation can streamline and optimize processes, increasing efficiency

Cost savings: Automation can lead to significant cost savings in the long term

Improved Quality and Accuracy: Automated systems are able to perform tasks with great precision, resulting in consistent product quality

Automation industry

Looking for a full-fledged partner in the field of industrial automation, and support from expert experts for whom no PLC system poses a problem? Hexapole is an international partner and expert in the field of industrial automation.

AIV: Autonomous Intelligent Vehicles

<p>Autonomous Intelligent Vehicles (AIV’s) are increasingly being integrated by companies into their organization for transporting products. The latest generation of mobile robot (Autonomous Intelligent Vehicles – AIV) moves itself autonomously through a space, even when there are constant movements of forklift trucks and people.</p>

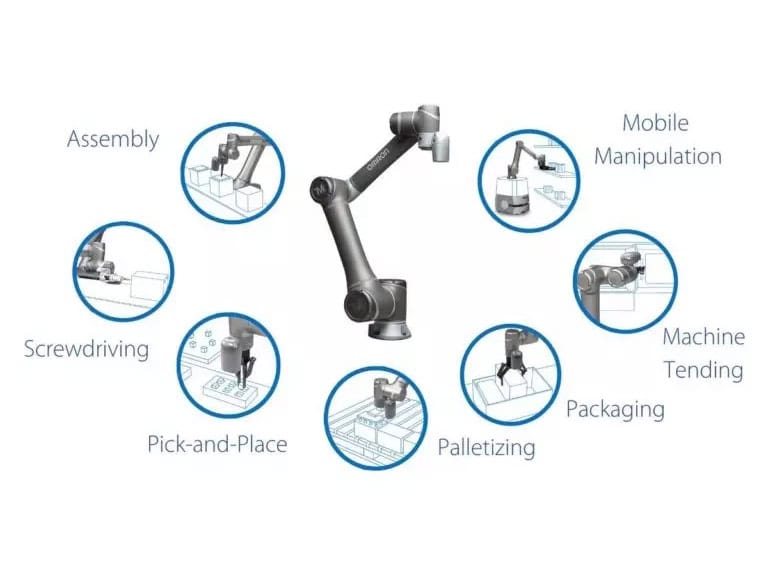

Cobots – Collaborative Robots

A cobot or collaborative robot is a robot that is intended to work together with people in a common working environment. A cobot therefore differs from other robots, which are designed to operate independently or with limited guidance.

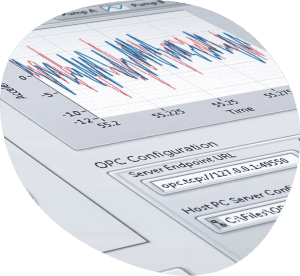

LabVIEW

LabVIEW is system software for applications that require testing, measurement and control with quick access to hardware and data insights. LabVIEW provides a graphical programming approach that allows you to visualize every aspect of your application, including hardware configuration, metrics and debugging.

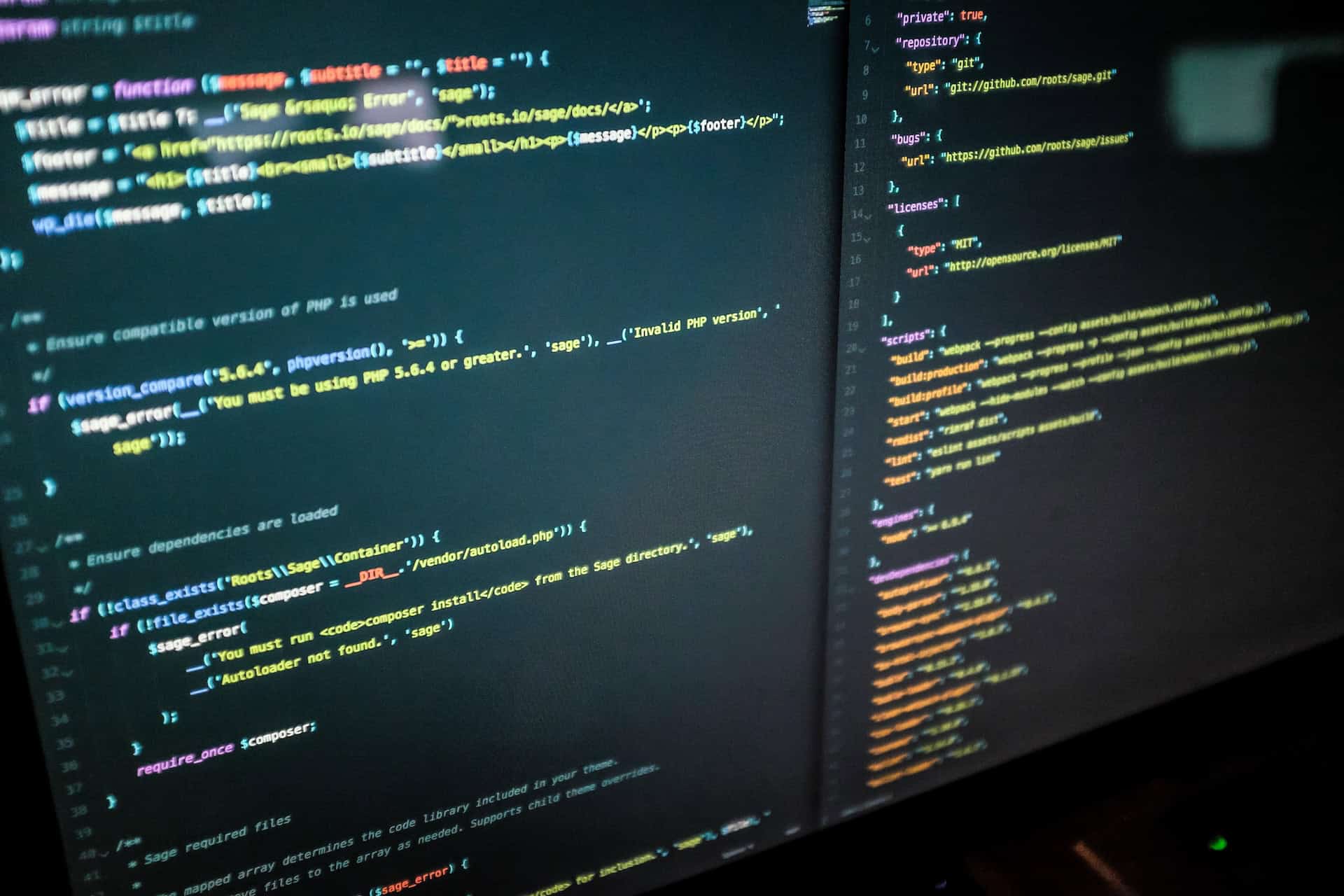

Software & IT

Industrial automation is not just about machines. Equally important is the operating software; the algorithms, the clear and easy-to-use screens, communication with the ERP or WMS and of course the control of the machine itself by means of a PLC.

Hexapole has almost 25 years of experience in building sorting software. Our Standard Sorting Software consists of a solid basis on which customer-specific modules can be placed. In addition to the Sorting Software (PC), Hexapole also supplies the complete machine control of the sorting machine itself (PLC).

PLC Engineering

In the industrial sector machines usually are controlled with PLCs, Programmable Logic Controllers. This makes these electronic devices with a microprocessor an important part of the daily routine. Indispensable, actually. When capacity issues occur or there is a lack of specific knowledge, we as experts in the area of industrial automation come into play.

Hexapole can provide both the PLC and the customer-written software for your company. By doing so, we ensure that the machines, and therefore the entire production process, operates optimally. Moreover, we can also integrate the PLC systems in a complete solution with SCADA, HMI and a database application.

Our experts

Programming all kinds of different types of PLCs is a daily routine for our PLC programmers. These very important devices, therefore, hold no secrets for the experts of Hexapole. Each and every one of them have extensive experience with, amongst others, working with Siemens, Allen Bradley, Beckhoff and B&R. PLCs generally also communicate with systems such as database applications, Remote I/O, sensors, cameras, barcode systems and other. Our PLC programmers, therefore, also create reliable connections, partly thanks to years of experience with different systems including Ethernet, EtherCAT, Profibus, Profinet, Modbus, CANbus and RS 232/485.

24/7 Support

When you choose Hexapole as your full partner for industrial automation, you can opt for our breakdown and support service, 24 hours per day, 7 days per week. Our emergency helpline number can always be reached, and we will try to solve your problems immediately and professionally. Not a regular customer, yet you do have a malfunction? Do not hesitate to contact us at +31 (0)72 – 303 40 50.

Never worry again about industrial automation

Are you looking for a full partner in industrial automation, and for support from professional experts for whom no PLC system poses a problem? Then do contact us free of obligation quickly at +31 (0)72 – 303 40 50 (landline). We look forward to discussing your wishes and needs, and how we can help you.

Frequently asked questions ‘Industrial automation’

What is automation?

Automation refers to the use of technology and systems to perform tasks or processes with minimal human intervention.

Why is automation important?

Automation is important because of its benefits such as improved efficiency, cost savings, increased accuracy and the ability to automate repetitive tasks.

Which tasks can be automated?

Repetitive, structured tasks with clear rules and patterns are suitable for automation. Examples include data entry, report generation and routine tasks.

What are the possible consequences of automation for employment?

Automation can lead to job losses in certain sectors, but also create new opportunities, especially in the development and management of automated systems.

How can I implement automation in my business?

Implementation requires a thorough evaluation of processes, investment in appropriate technologies, training of staff and gradual integration of automation into business operations.

What are the ethical considerations of automation?

Ethical considerations include issues such as privacy, security, transparency and the impact of automation on employment and social structures. It is important to follow ethical guidelines when developing and implementing automated systems.