Software & IT

Industrial automation do not only consist of machines. Just as important is the operating software; algorithms, clear and user friendly user interface, communication with the ERP or WMS and of course the software-based control of the actual machine by use of a PLC.

Hexapole has almost 25 years of experience in building sorting software. Our Standard Sorting Software consists of a solid basis on which customer-specific modules can be placed. In addition to the sorting software (PC), Hexapole also supplies the complete machine control of the sorting machine itself (PLC). Our Standard Sorting Machine Control Software is available for Siemens S7 and Beckhoff. We also have experience with B&R and Allen Bradley.

Sorting Software (PC)

Hexapole has almost 25 years of experience in creating sortation software. Our Hexapole Standard Sortation Software consists of a solid basis to which customer specific modules can be added. For example a customer specific sortation algorithm that takes sales history and shop sizes into account.

Also the communication with the higher-level ERP or WMS system can be arranged according customer wishes. Communication can take place through one of the following techniques:

- Shared database

- TCP/IP messages

- Individual files

For all the above we can use our standard modules and make changes according to customer wishes.

Complete handling of related systems

Our sortation software does not only consist of a sortation algorithm. We can control any related system. For example:

- Automatic barcode readers or cameras for reading product barcodes.

- Manual barcode scanners for reading barcodes of boxes and stations.

- RFID antenna’s to automatically detect articles.

- Volume scanners on conveyor systems or measuring volumes directly in a tray.

- Weighing systems to verify weights of boxes coming from sorting machine.

- Label printers for printing a carrier label for a box.

Functionality of our Standard Sortation Software:

- Multilingual user interfaces.

- Choice of various kinds of sortation algorithms.

- Operator displays at induction points.

- Box volume optimisation.

- Management control; changing an individual SKU or manipulation of the content of the batch.

- Standard progress information; totals sorted and to sort, utilization, articles per hour per induction point.

- SCADA system; detailed information about the status of the machine.

- Reporting to the ERP or WMS; box content data and shortage information.

- Mechanical maintenance information; statistic around faulty trays and stations.

- Possibilities to show live management information on systems within the customer’s private network and portable equipment (like a tablet).

Sending / Dispatching

Besides sortation software, we can completely arrange the steering and management of the dispatching process, a standard procedure is as follows:

- Automatically scanning boxes.

- The ability to scan a box manually if something went wrong.

- Automatic shipping-label printing.

- Automatically close and duct-tape boxes.

Management information

Especially for management and supervisors we offer detailed management information and data. The data can be displayed via web-browser and not only on the local computer screen but also via any other computer or tablet connected to the internal network. Information can be as follows:

- Total products, either per hour or/and per input-station.

- Total amount of full boxes per hour.

- The production capacity of the machine against the number of processed items per input-station.

- Overview of the amount of full stations during a chosen time-window.

- Current problems or errors in the installation.

Are you interested in more information about our software solutions?

Feel free to contact us.

Or call directly with +31 (0) 72 – 303 40 50.

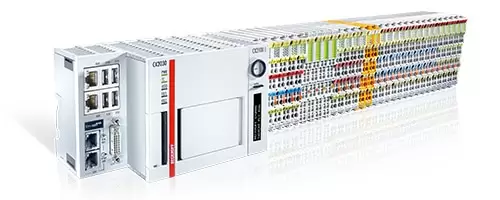

Programmable Logic Controller (PLC)

Besides the Sortation Software (PC), Hexapole delivers the complete Programmable Logic Controller (PLC) of the sortation machine itself. Our standard sortation machine-control software is available for Siemens S7 and Beckhoff. We also have experience with B&R and Allen Bradley.

Our standard sortation machine-control software controls and manages the following components:

- The sortation machine itself.

- In- and outbound conveying systems.

- Conveying systems for supplying the machine with empty boxes.

- Automatic infeed conveyors.

Specially for hangers sortation machines:

- Synchronized input spindle.

- Hook separator.

- Double hanger detection.

Safety System

Safety around the sortation machines delivered by Hexapole is of the utmost importance for us, after all that’s what the client expects and is stated in the law. Our sortation machines are delivered with extended safety system. We attend and care for the whole technical aspect and offer our services during the machine’s whole lifecycle. Our safety systems are always conform the international CE compliant.

Our Safety System is delivered with an extended SCADA system where you can find detailed information over the status of the machine and the Safety System. If a safety element becomes active the screen will clearly display which element it concerns and where to find it exactly in the machine, this will allow the operating personnel to quickly solve the problem and resume production.

Are you interested in more information about our machine-control software?

Feel free to contact us.

Or call directly with +31 (0) 72 – 303 40 50.

Service and Maintenance

Hexapole delivers a full service contract with the sortation machine, with that we can guarantee the operationality of the machine, and the maximum continuity for distributing your products will be insured.

We also deliver custom installations based on your business:

- The ability to support remotely.

- Weekly preventive server-checks.

- Monthly checking the integrity of the backup process.

- Yearly preventive mechanic maintenance.

- Reached via the telephone during office hours (or 24/7 or custom timeframe if needed).

- Response time of 4 hours or 2 hours (or custom if needed).

- Packages with extra spare parts.

Are you interested in more information about our service contracts? Feel free to contact us. Or call directly with +31 (0) 72 – 303 40 50.